熱搜關(guān)鍵詞:

CNC precision machining technology has revolutionized the manufacturing industry, offering unparalleled precision, efficiency, and versatility. From producing intricate components for aerospace to crafting delicate medical devices, CNC machining plays a pivotal role in various sectors. This article delves into the myriad advantages and applications of CNC precision machining technology.

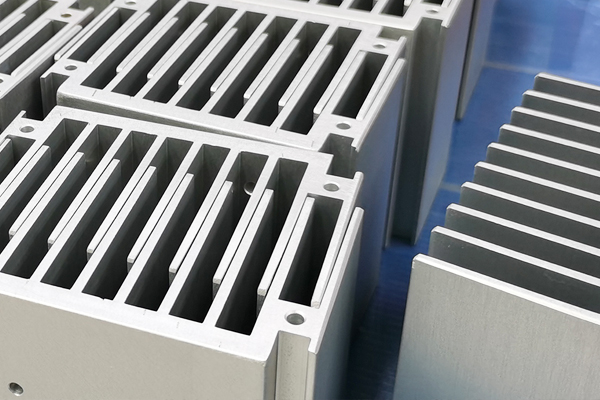

CNC precision machining boasts numerous advantages over traditional manufacturing methods. Firstly, it enables unmatched precision, with tolerances measured in microns, ensuring consistent quality and accuracy. Secondly, CNC machines are incredibly efficient, capable of running continuously with minimal human intervention, thereby reducing production times and costs. Additionally, CNC machining offers unparalleled versatility, allowing for the production of complex geometries and customized components with ease.

The applications of CNC precision machining span across various industries. In aerospace, CNC machining is utilized to fabricate critical components such as turbine blades and structural elements with exceptional precision and durability. In the medical field, CNC machining plays a crucial role in producing intricate implants, surgical instruments, and prosthetics tailored to individual patient needs.

Moreover, CNC precision machining finds extensive use in the automotive sector for manufacturing engine parts, transmission components, and chassis components with high dimensional accuracy and reliability. Additionally, the electronics industry relies on CNC machining for crafting circuit boards, connectors, and housings with intricate features and tight tolerances.

Looking ahead, the future of CNC precision machining is marked by continuous innovation and technological advancements. Emerging trends such as additive manufacturing and hybrid machining are reshaping the landscape, offering new possibilities in terms of material choices, design freedom, and production efficiency. Furthermore, the integration of artificial intelligence and machine learning algorithms into CNC systems promises to further enhance productivity, optimize tool paths, and minimize waste.

In conclusion, CNC precision machining technology stands as a cornerstone of modern manufacturing, offering unparalleled precision, efficiency, and versatility across various industries. As technology continues to evolve, the potential for innovation and advancement in CNC machining remains limitless, driving the ongoing transformation of the manufacturing landscape.

------------------------------------------------------------------------以上內(nèi)容是由深圳捷百瑞科技有限公司資深加工工藝師分享,捷百瑞精密廠家專業(yè)從事精密零件加工、非標(biāo)零件加工、高端產(chǎn)品殼體加工、從定制設(shè)計到加工落地的機械加工廠家。公司自2013年成立來,加工的各類高端殼體和高精度零件加工案例達12000多種,專業(yè)的工程技術(shù)團隊為客戶提優(yōu)質(zhì)的服務(wù),歡迎各界朋友蒞臨我司指導(dǎo)和業(yè)務(wù)洽談!(文章來自http://cbcgcv.com) 歡迎咨詢!

【本文標(biāo)簽】 鋁件數(shù)控加工 鋁制品cnc加工 鋁合金加工 精密cnc零件加工

【cnc五金加工廠家】版權(quán)所有

咨詢熱線

13751188387